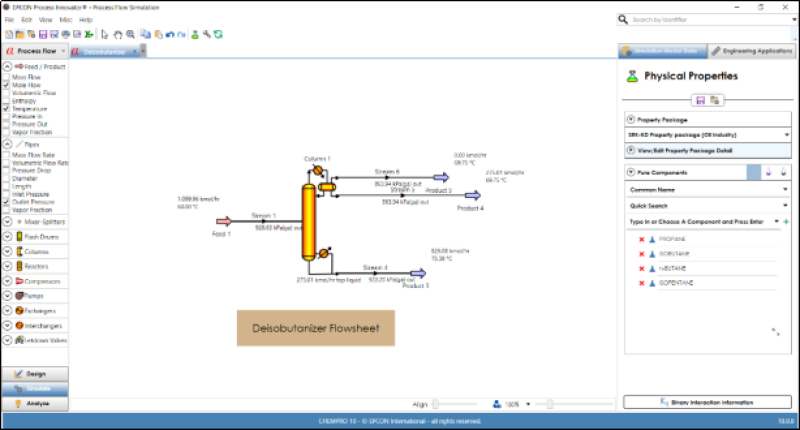

CHEMPRO Engineering Suite

Ultimate Precision in Fluid Flow and Process Simulation Solution

Seamlessly Create Steady-State for Your Plant Design in One Unified Environment.

CHEMPRO Engineering Suite is your comprehensive solution for fluid flow and process simulation. It provides the tools and insights needed to drive innovation and achieve exceptional results in engineering projects. Discover how CHEMPRO can enhance your processes and deliver superior performance.

For more information, please visit epcon.com

Enhance plant performance by refining models with real-time operating data.

Achieve rapid flowsheeting for steady-state and dynamic modeling, minimizing expenses.

Align designs with your operational goals for optimal performance.

Easily create and visualize process flowsheets with our intuitive platform, designed for seamless usability.

Unlock your process design potential with CHEMPRO Engineering Suite. This top solution for fluid flow and process simulation delivers unmatched precision and efficiency. Designed for engineers, our intuitive platform enables seamless design and analysis. Streamline your workflow with accurate simulations that drive innovation and exceptional results.

Automatically generate pseudo-components from D86, D2887, or TBP crude assays along with API or Specific Gravity. These components and their mole percentages are used to determine phase splits and properties in flash calculations. A databank of SRK-KD and NRTL parameters is included, ensuring high-quality results for 2-phase and 3-phase flash. Use the View Binary Parameters button to display coverage of binary pairs, and access experimental VLE data from DDBST to create custom binary parameters.

CHEMPRO Engineering Suite is widely used across several key industries to optimize process design and improve operational efficiency. These industries include:

Within these industries, CHEMPRO Engineering Suite serves a variety of roles and applications:

Process Engineers and Consultants: They utilize the suite for margin optimization, retrofit analysis, and energy/greenhouse gas (GHG) optimization, ensuring operational efficiency and sustainability throughout the process lifecycle.

Process and Technical Service Engineers: These professionals use CHEMPRO Engineering Suite for off-line optimization, conducting what-if analysis and post-event investigations to continuously improve plant performance and address operational challenges.

Try out scenarios in a virtual environment before implementing the improvement in the actual plant.

DOWNLOAD PIN

Data without direction is noise. Turn complex first principal models and material balance flowsheets into actionable insights.

ACCESS WHITEPAPER

Learn about ENI Digital Twin and how it can help your plant reach optimization, efficiency, and sustainability goals.

REGISTER TO WATCH

Discover our cutting-edge fluid flow and process simulation solutions that redefine excellence. Choose CHEMPRO-where advanced technology and precision engineering converge for unparalleled results.

Request a Consultation