SINET Fluid Flow Simulator

Precision Hydraulic Modeling & Advanced Fluid Flow

Optimize Your Fluid Systems with SINET – Where Innovation Meets Precision.

Unlock unmatched precision and efficiency with the SINET Fluid Flow Simulator, the leading solution for fluid flow simulation. Perfect for both liquids and compressible gases, SINET's advanced Process Innovator interface allows for seamless optimization and analysis of fluid systems. With over 30 years of industry expertise, EPCON delivers an intuitive tool that sets the standard in fluid flow and process engineering. Elevate your projects with SINET and experience superior performance today!

For more information, please visit epcon.com

Harness real plant operating data to fine-tune your fluid flow models, enhancing energy efficiency and reducing emissions effectively.

Achieve rapid and efficient flowsheeting for both steady-state and fluid flow modeling, significantly lowering operational costs.

Optimize your designs to meet critical operational and business goals, maximizing both performance and profitability.

Easily design and visualize fluid flow flowsheets with our intuitive interface, making fluid flow simulation simple and accessible for all users.

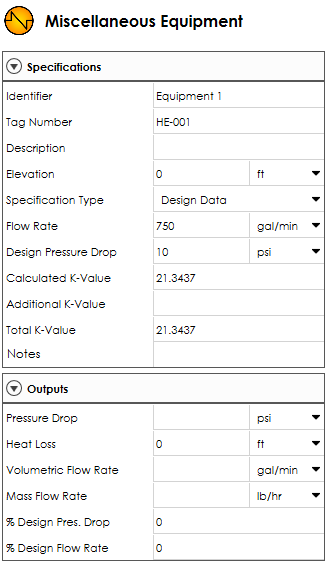

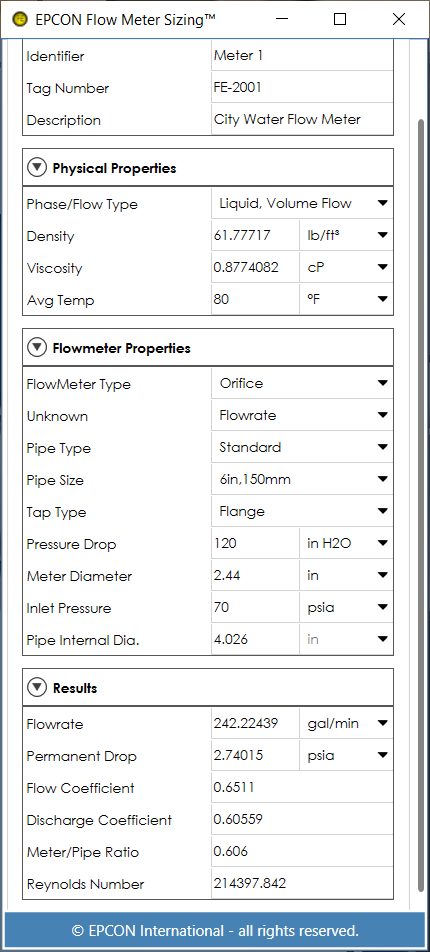

EPCON’s suite of sizing applications simplifies the design process across various types of equipment:

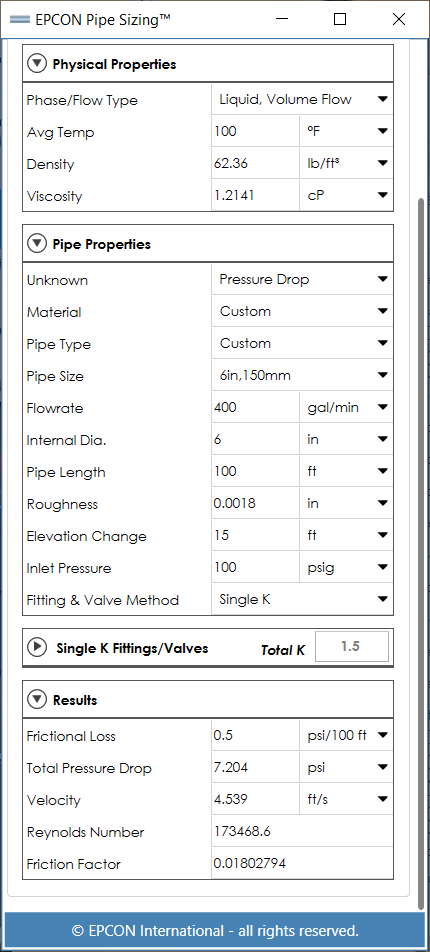

Calculate flow rate, pressure drop, or diameter for single-phase flows with precision.

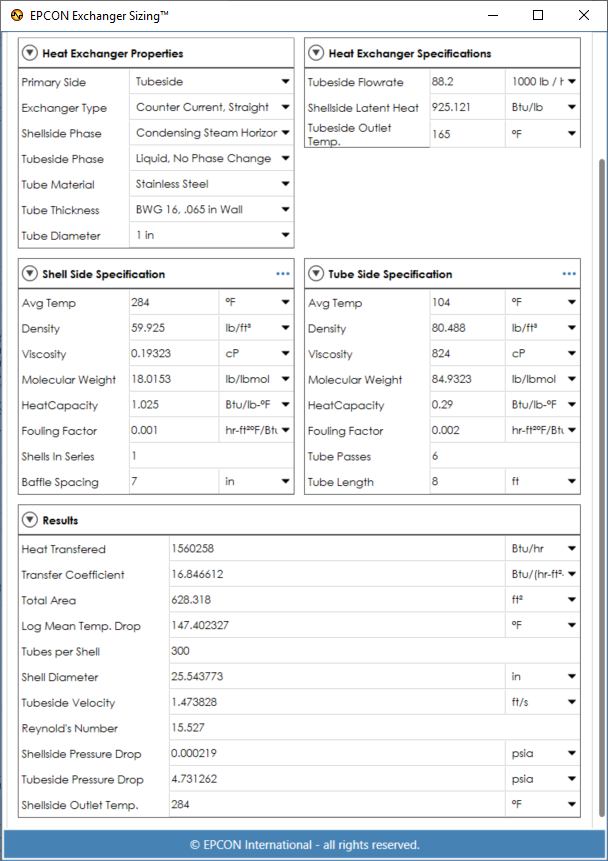

Efficiently size Shell and Tube heat exchangers for any liquid or gas combinations without requiring thermal conductivity data.

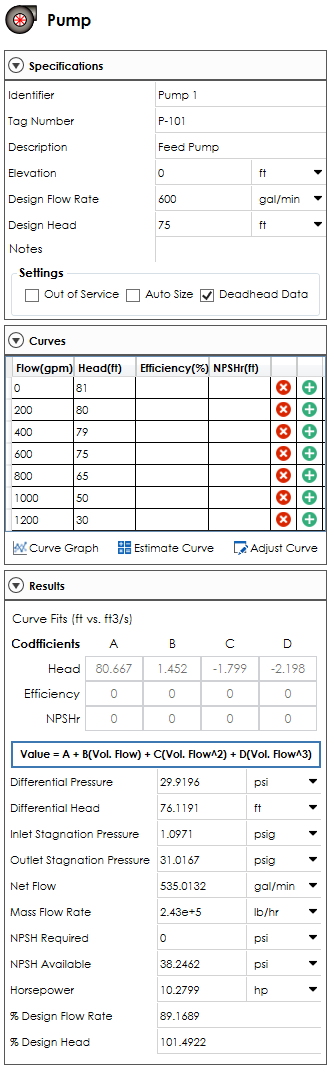

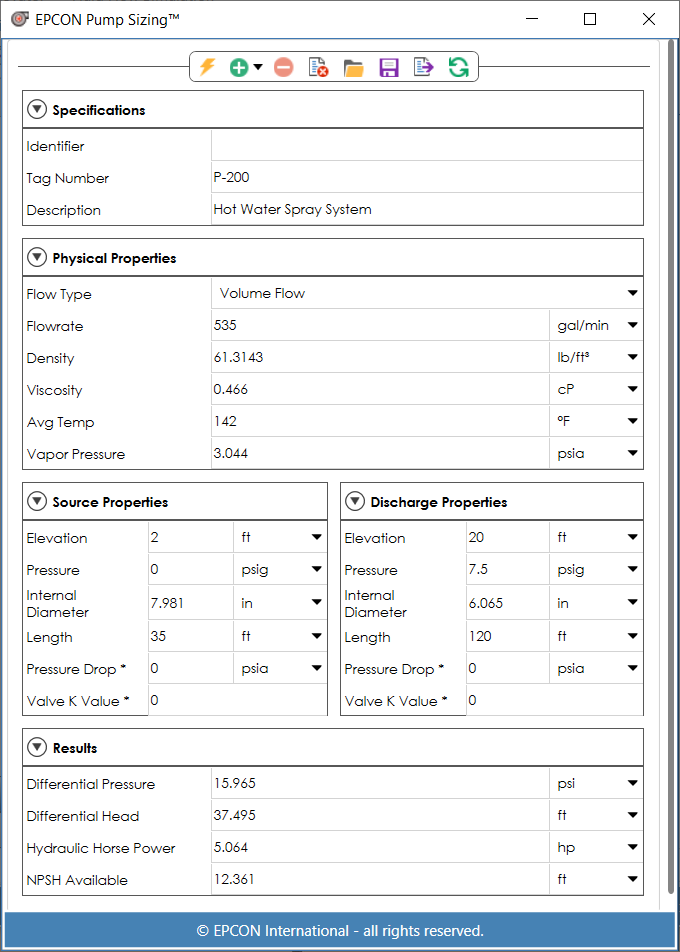

Determine differential head, hydraulic horsepower, and NPSH available for pumping systems with accuracy.

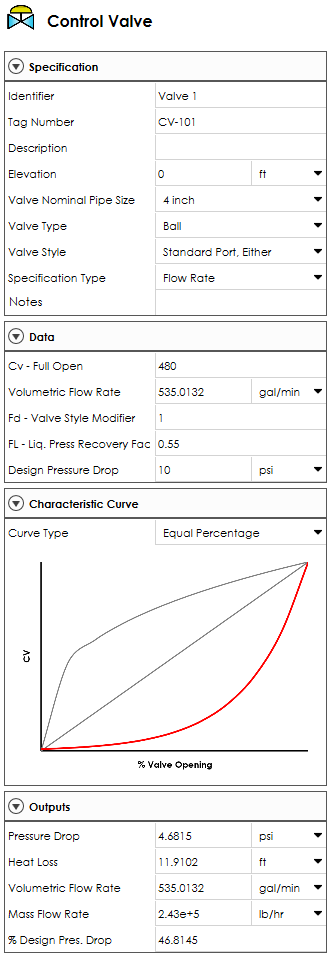

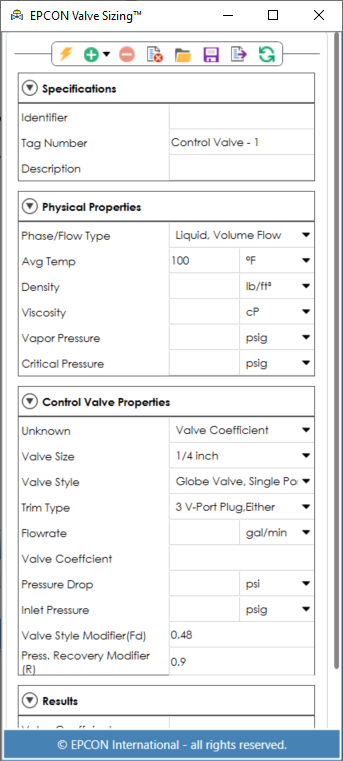

Size control valves for both gases and liquids, addressing pressure drop and sizing coefficient needs effectively.

Accurately size relief valves according to ASME pressure vessel codes, ensuring compliance and safety.

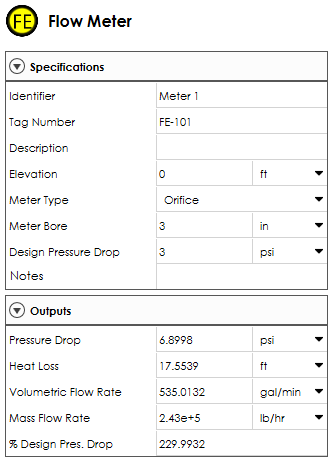

Size orifice plates, venturi tubes, and flow nozzles with precise calculations of pressure drop and flow rate.

The SINET Fluid Flow Simulator, powered by EPCON’s Process Innovator interface, offers advanced hydraulic modeling and analysis for both liquid and gas systems. Key features include:

See what makes SINET different and learn about real-world results.

VIEW INFOGRAPHIC

Learn about solving challenges and optimizing processes in the green hydrogen field.

ACCESS WHITEPAPER

Contact us today to discover how the SINET Fluid Flow Simulator can help you achieve your operational goals and optimize your fluid and gas systems.

Request a Consultation