ENI Analytics: Transform your operations with

ENI Analytics: Transform your operations with

Optimize Efficiency & Boost Performance

Advanced Digital Twin and Engineering Solutions

Get Started

Together, let's create a sustainable future

At ENI, we are dedicated to leading the energy transition through innovation and sustainability. By optimizing systems and leveraging advanced technologies like digital twins, we aim to reduce carbon emissions and enhance resource efficiency.

Learn More

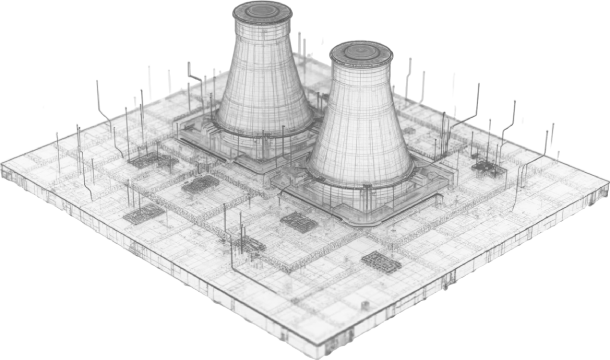

Transforming industry efficiency

Unlock unparalleled efficiency with digital twin technology. Create virtual models for real-time insights, predictive maintenance, and cost reduction. Optimize industrial processes with our advanced solutions.

Learn MoreAdvanced Fluid Flow Simulation & Process Engineering Software

Explore EPCON's CHEMPRO Engineering Suite, featuring SINET Fluid Flow Simulation and rigorous thermodynamic models for in-depth engineering design and optimization.

Learn MorePrecision Hydraulic Modeling & Advanced Fluid Flow

Discover EPCON's SINET Fluid Flow Simulator, the ultimate solution for precision hydraulic modeling and advanced fluid analysis. Seamlessly design, simulate, and analyze both liquid and gas systems with cutting-edge features including automated equipment sizing, Smart Fittings™ technology, and an extensive component database. Optimize your process engineering with SINET — where innovation meets accuracy.

Learn More

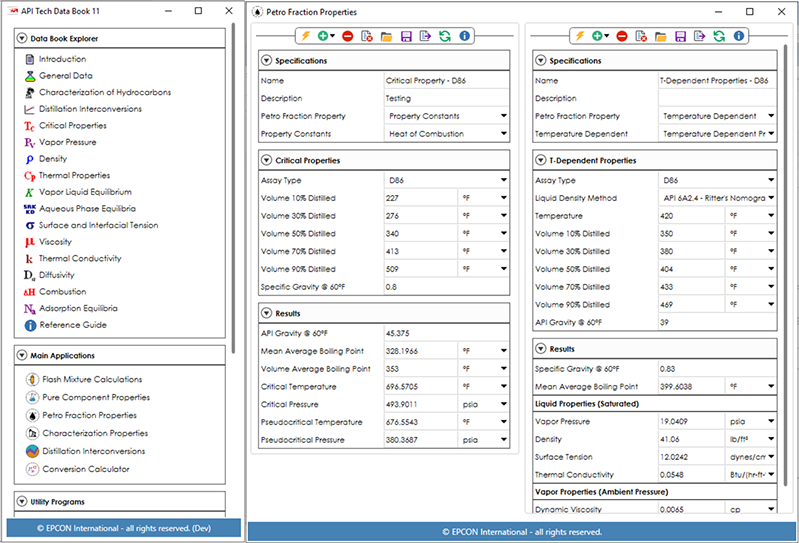

Unmatched Precision in Refinery Thermodynamics and Data Analysis

Discover EPCON's API Technical Data Book 11 – the ultimate resource for advanced refinery thermodynamics. Featuring powerful tools like THERMA Pro™ for accurate 3-phase flash calculations, comprehensive pure component and Petro fraction properties, and a suite of essential utility programs. Elevate your refinery analysis and optimize your processes with cutting-edge features and unmatched accuracy.

Learn More

Transforming Pipeline Challenges into Opportunities

Discover our expert services in Pipe Network Analysis and Optimization. Identify bottlenecks, enhance energy efficiency, and ensure reliable operation of your pipeline systems.

Learn More

Elevate Plant Efficiency with ENI's Cutting-Edge Engineering Solutions

Discover how EPCON's CHEMPRO advanced process engineering software can significantly boost plant efficiency and profitability. Our comprehensive process case study showcases precision simulations, including columns, compressors, exchangers, and more, all backed by our award-winning team. Learn how ENI leads the way in process optimization.

Learn More

We have successfully collaborated on numerous projects with our global clients, analyzing millions of data points using advanced digital twin technology, monitoring systems, and process engineering software. Our track record demonstrates our ability to deliver impactful results, optimizing performance and efficiency across various industrial processes.

Our dedicated team excels in understanding and mitigating complex challenges within process systems. We have a proven track record of assisting companies in troubleshooting issues effectively. Leveraging advanced digital twin technology, we provide insights that enhance system performance and operational efficiency.

Our cutting-edge technology, developed with extensive industrial input, has been successfully applied in numerous projects across various sectors. Our digital twin models are validated for their predictive capabilities using real industrial data, enabling effective monitoring, prediction, management, and mitigation of complex challenges in the field. With our process simulation engineering software and advanced monitoring systems, we empower organizations to enhance operational efficiency and drive innovation.

We take a customer oriented approach, backed by extensive experience in both small and large scale digitalization projects. Our collaborative work with client teams across Engineering and Operations has garnered praise for our flexibility and unwavering focus on customer success. Whether through ad-hoc consultancy, regular monitoring services of software supply, we partner with your teams to deliver exceptional value to your organization.